Our blogs feature all things home remodeling, design and build with wide-flung interpretation. Here we cover design concepts for kitchens, bathrooms, and home additions. We also cover green building, building science and building materials. In the wider-flung reaches we cover urban design, the psychology of happiness and celebrations of those things. We are also happy to take and answer your questions.

Check out the recent articles written about us:

Sense of Place: Lighter + Brighter Homes

Your home is a special place. It should be your

Big Cedar Estates Remodeling Project

This project, located in Big Cedar Estates in College

Elevate Your Bathroom Experience: Must-Have Features for Your Dream Custom Shower

Did you know the average person spends around 60

2024 Colors of the Year

Hey there, design enthusiasts! Can you believe it? We're

Home for the Holidays

Ah, the holidays - a whirlwind of festivities, joy,

North Oakwood Historic Remodel

Embarking on this remodeling project was a one-of-a-kind experience,

Why You Should Consider an Induction Cooktop for your Kitchen

For years, the battle between gas and electric cooktops

Devonshire Neighborhood Bathroom Remodel

Embarking on this project was an exhilarating journey that

Edelweiss Estates Patio Addition

Sprucing up the backyard: A patio transformation story!

Enhancing Energy Efficiency: The Foundation of Every Project at Stearns Design Build

At Stearns Design Build, we don’t just construct houses;

Briarcrest Neighborhood Remodel

We couldn't have asked for a more delightful project

All About Lighting

Brighten up your living spaces with the magic of

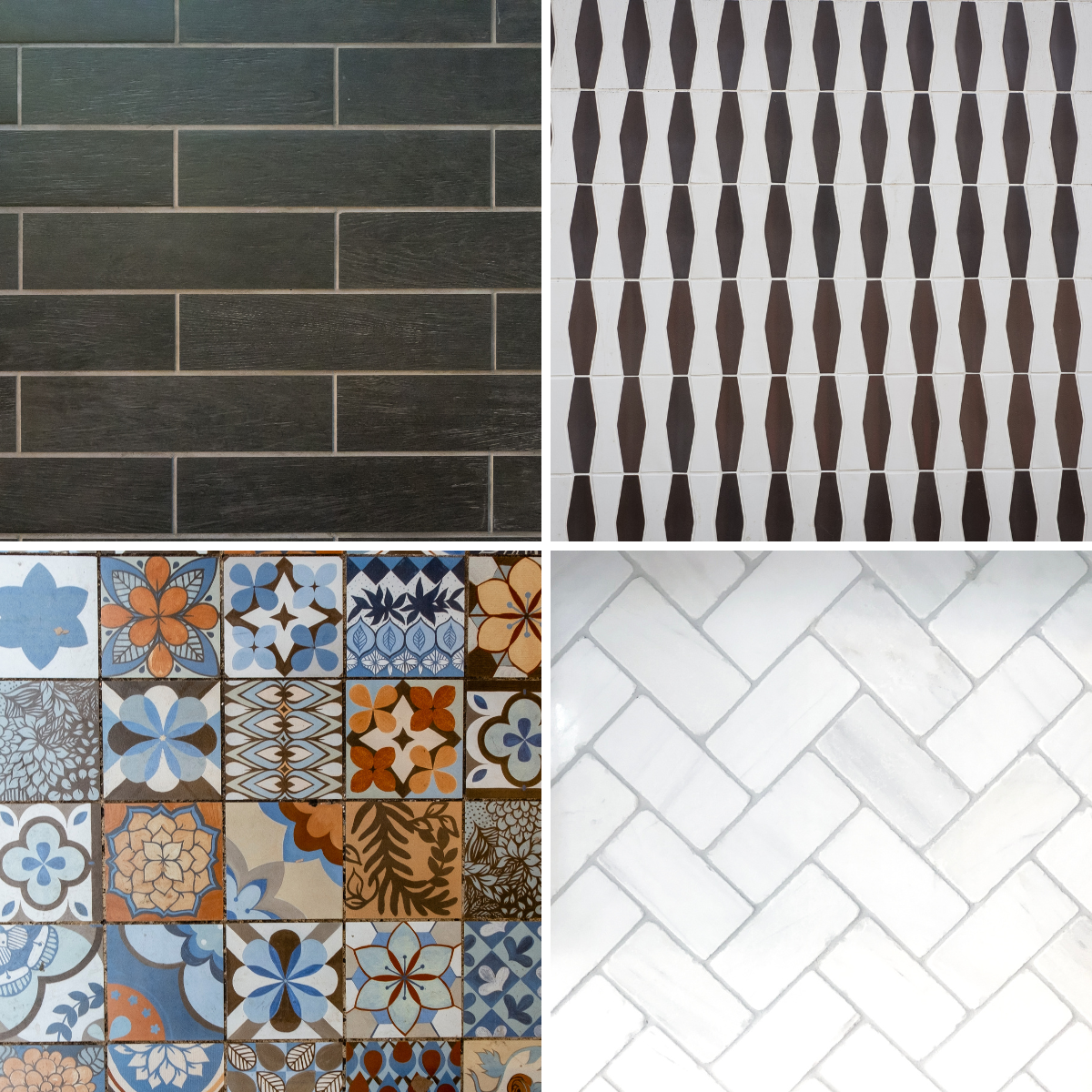

Enhancing the Look of Your Kitchen and Bathroom Design with the Right Grout Color

Our designer, Preston McMath, is here to discuss choosing

Whole Home Remodel in Emerald Forest

We were delighted to be able to take on

What Countertop Should I Choose?

Our designer, Preston McMath, is here to discuss a